AMAC Pneumatic and Hydraulic Clamp Components Automated Machine Accessories Clamps

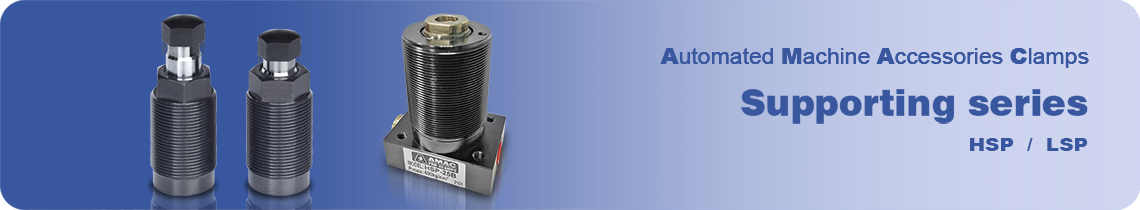

Hydraulic Supporting Cylinder Series

HSP-16 High pressure supporting cylinder / Rod : ø16mm

HSP-25 High pressure supporting cylinder / Rod : ø25mm

Low pressure supporting cylinder / Rod : ø16mm

Product Introduction

• Pmax : 500 Kg/cm²

• The hydraulic supporting cylinder is normally applied for machining, which may reduce vibration, prevent deformation, absorb cutting force while upgrading machining accuracy and quality.

• The hydraulic cylinder employs imported oil seal and parts to resist high pressure, and ensure quality dependability and long service life.

• When operating the supporting cylinder, make sure do not exceed the normal oil feeding speed to avoid the supporting bar bumping against workpiece when it contacts workpiece.

• The HSP-16 screw type cylinder compact construction permits several units operated for clamping in a small space.

• The LSP-16B low pressure supporting cylinder achieves a high pressure supporting capability, hydraulic system and with in 50kg/cm2 of operation pressure.

Model Identification

• A Type: A spring ejecting type. The supporting bar is located at the highest position. The spring controls contact force when the workpiece is contacting the supporting bar. The hydraulic power actuates oil feeding for tightening the shaft, producing a supporting force.

• B Type: A hydraulic ejecting type. The supporting bar is located at the lowest position. The hydraulic power actuates oil feeding for ejecting. The spring controls contact force against the workpiece. The hydraulic power then tighten the shaft to produce a supporting force.

Notice

• The supporting nut on the HSP-16 and LSP-16B can be replaced as shown on the figure right. An O-ring provided on the neck is used for sealing the center hole of supporting bar. The O-ring must be fitted, which should not be thrown away.

•When the LSP-16B uses the same single acting hydraulic cylinder with other jigs, the circuit for the supporting bar should be controlled individually when applying for the same jig.