AMAC Pneumatic and Hydraulic Clamp Components Automated Machine Accessories Clamps

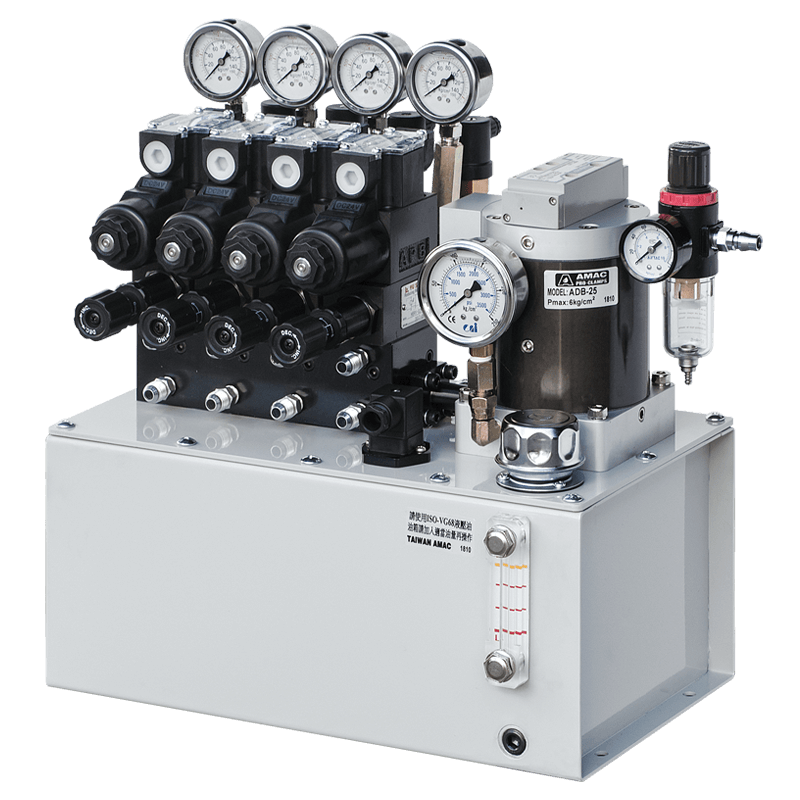

Air drive booster - Air Pump Four Circuit

Product Introduction

• Pmax:6kg/cm²

• The body of the booster cylinder has the same actuating function as the single circuit. The output hydraulic pressure includes four circuit. The P port on each circuit is equipped with a single direction valve, so that each circuit can work individually.

• Optional Accessories: Fluid level switch in oil tank EP-125FA

• Modular pressure reducing valve (Max operation pressure 210kg/cm²)

MBRV-02P-1L:3~35kg/cm²

MBRV-02P-2L:7~70kg/cm²

MBRV-02P-3L:35~140kg/cm²

MBRV-02P-1L:3~35kg/cm²

MBRV-02P-2L:7~70kg/cm²

MBRV-02P-3L:35~140kg/cm²

• Pressure sensor : Made in TAIWAN

JC-PS-02L:10~230kg/cm²

JC-PS-02LL:5~60kg/cm²

JC-PS-02L:10~230kg/cm²

JC-PS-02LL:5~60kg/cm²

• Pressure sensor : Made in ITALY

PS-021:20~50kg/cm²

PS-022:50~80kg/cm²

PS-023:50~150kg/cm²

PS-021:20~50kg/cm²

PS-022:50~80kg/cm²

PS-023:50~150kg/cm²

Specification

| Fluid | Filtered air | |||||

| Max operation pressure | 6 Kg/cm² | |||||

| Boost pressure rate | 06 | 10 | 13 | 18 | 25 | 44 |

| Air pressure supply6 Kg/cm² | 15.1 | 10.8 | 8.9 | 5.9 | 4.9 | 3.2 |

| Hydraulic fluid expelledL/min | ||||||

| Oil tank capacity | 12 L | |||||

| Oil | ISO-VG68 | |||||

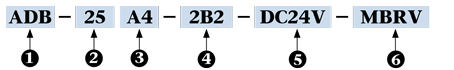

Order Code

| 1 | Series | ADB | |

| 2 | Boost pressure rate | 06 , 10 , 13 , 18 , 25 , 44 | |

| 3 | Control type | Four-circuit manifold plate with ISO specification. | |

| 4 | Direction change valve type | Single Head : 2B2-02, Double Head : 2D2-02,3C2-02 |

|

| 5 | Coil type | AC110V,AC220V,DC24V | |

| 6 | The pressure reducing valve model | MBRV1,MBRV2 MBRV3,MBRV4 |

|

Notice

• Use ISO-VG68 hydraulic oil. Be sure to fill proper amount of hydraulic oil into the oil tank before operation.

• Periodically inspect hydraulic oil quality to prevent affection on normal operation and parts life.

• In case air system can’t work, remove the air valve but do not break down. Use an air gan to clean the internal direction change ports.

• There is a thin type bronze silencer on the aluminum body of air cylinder. If it is blocked by suction of powder dust, it may impede the motion of the piston of air cylinder. When such problem occurs, remove it for cleaning or replacing.

• If air system works continuously, but hydraulic pressure can’t boost, it means oil seal is damaged causing internal leakage.